Working at height involves tasks where employees are at risk of falling from a height, requiring thorough risk assessment to ensure safety and compliance with regulations.

What Constitutes Working at Height?

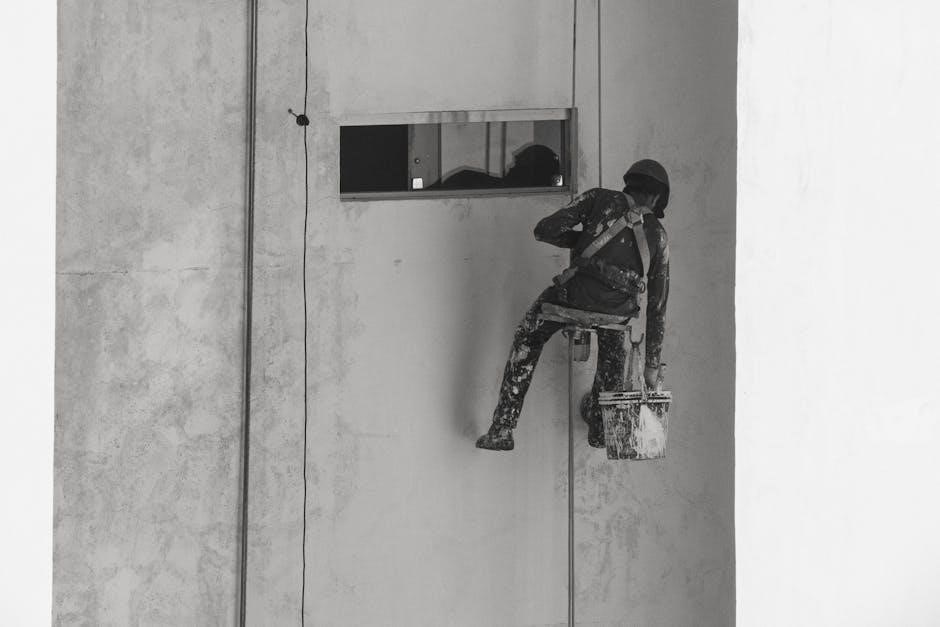

Working at height refers to any task where a person could fall from a height, potentially causing injury or death. This includes activities on ladders, scaffolding, mobile elevating work platforms (MEWPs), or fragile surfaces like rooftops or glass. Even below ground level, such as in trenches or pits, working at height applies if a fall could occur. The risk assessment process identifies these scenarios to implement safety measures. It is not limited to extreme heights; any elevation that poses a fall risk qualifies. Understanding what constitutes working at height is critical for ensuring compliance with safety regulations and protecting workers. Proper equipment inspection and maintenance are essential.

Importance of Risk Assessment in Height-Related Tasks

Risk assessment is critical for minimizing hazards in height-related tasks. It systematically identifies potential dangers, such as falls from ladders or scaffolding, and prioritizes control measures. By evaluating risks, employers ensure compliance with regulations like the Management of Health and Safety at Work Regulations 1999. A thorough assessment enables the implementation of safety protocols, reducing incidents and injuries. Tools like risk assessment matrices help quantify risks, guiding decisions on equipment and training. Regular reviews of assessments adapt to changing work conditions, ensuring ongoing safety. This proactive approach protects workers and organizations, fostering a safer working environment at heights. Effective risk assessment is the cornerstone of height safety management.

Legal and Regulatory Framework

The legal framework for working at height includes regulations like the Management of Health and Safety at Work Regulations 1999 and the Work at Height Regulations 2005, ensuring safety and compliance.

The Management of Health and Safety at Work Regulations 1999

The Management of Health and Safety at Work Regulations 1999 requires employers to conduct risk assessments for all work activities, including those at height. These assessments must identify potential hazards, evaluate risks, and implement control measures to ensure employee safety. Employers are legally obligated to provide safe systems of work, proper training, and necessary equipment to minimize risks. The regulations emphasize the importance of regular inspections and maintenance of equipment used in working at height, such as ladders and scaffolding. Compliance with these regulations is crucial to prevent accidents and ensure a safe working environment for employees engaged in height-related tasks.

Key Regulations and Standards for Working at Height

Key regulations and standards for working at height include the Work at Height Regulations 2005, which outline specific duties for employers, employees, and contractors. These regulations emphasize the need for risk assessments, proper equipment selection, and safe systems of work. Standards such as BS 8454:2006 (for mobile elevating work platforms) and EN 13374:2018 (for temporary structures) provide detailed guidance on equipment design and safety. Compliance with these regulations ensures that work at height is conducted safely, minimizing the risk of falls and injuries. Employers must also ensure that all equipment is regularly inspected and maintained to meet these standards.

Hazard Identification for Working at Height

Hazard identification is critical to ensure a safe working environment at heights, focusing on risks like unstable surfaces, equipment failure, and human error, which can lead to falls.

Common Hazards Associated with Working at Height

Common hazards include unstable surfaces, equipment failure, and human error, which can lead to falls. Environmental factors like weather and poor lighting exacerbate risks. Misuse of ladders and scaffolding is prevalent, while falling objects and structural instability further endanger workers. Regular inspections and proper training are essential to mitigate these risks effectively.

Psychological and Environmental Factors in Height-Related Risks

Psychological factors, such as stress, anxiety, and fatigue, can impair judgment and increase the likelihood of accidents. Environmental conditions like rain, snow, or wind can make surfaces slippery or unstable, while poor lighting may reduce visibility. These factors, combined with the physical risks of height, create a complex safety challenge. Workers may also experience vertigo or loss of focus, further elevating risks. Addressing these psychological and environmental elements is critical in any risk assessment to ensure safe working conditions and prevent incidents. Regular breaks, proper training, and adaptive equipment can help mitigate these challenges effectively.

Risk Assessment Process for Working at Height

The process involves planning, hazard identification, risk evaluation, and implementing control measures to ensure safe working conditions at height, guided by regulatory standards and safety protocols.

Step-by-Step Guide to Conducting a Risk Assessment

Conducting a risk assessment for working at height involves several structured steps. First, identify the specific activity and associated hazards, such as equipment malfunctions or unstable surfaces. Next, evaluate the risks by considering the likelihood and potential impact of each hazard. Implement control measures, such as using fall protection equipment or ensuring proper scaffold inspection. Monitor the effectiveness of these controls and regularly review the assessment to adapt to changing conditions. Finally, document the process and communicate findings to all involved parties to ensure a safe working environment; This systematic approach ensures compliance with safety standards and minimizes height-related risks effectively.

Tools and Templates for Risk Assessment (e;g., Risk Assessment Matrix)

Various tools and templates are available to facilitate effective risk assessments for working at height. A Risk Assessment Matrix helps evaluate hazards by categorizing them based on likelihood and impact. Templates like the Working at Height Risk Assessment Form provide structured formats for documenting hazards, controls, and responsibilities. Checklists, such as pre-job safety inspections, ensure consistency in identifying risks. Additionally, organizations like Frasers Livestock Transport offer Risk Assessment Programs tailored for height-related tasks. These resources streamline the assessment process, ensuring thorough identification of risks and implementation of appropriate control measures. Regular updates to these tools reflect evolving safety standards and best practices in height safety management.

Control Measures for Minimizing Risks

Implementing control measures such as fall protection equipment, scaffolding, and MEWPs minimizes risks. Regular inspection and maintenance of equipment ensure safety. Proper training and supervision are essential.

Equipment Inspection and Maintenance (e.g., Ladders, Scaffolding, MEWPs)

Regular inspection and maintenance of equipment like ladders, scaffolding, and MEWPs are critical for ensuring safety. Always visually inspect equipment before use to identify any damage or wear. Ladders must be checked for structural integrity, while scaffolding should be verified for stability and proper assembly. MEWPs require thorough examination of hydraulic systems, brakes, and control functions. Defects must be reported and addressed promptly to prevent accidents. Maintenance records should be kept, and equipment should be serviced according to manufacturer guidelines. Proper storage and handling of equipment also play a role in maintaining its reliability. Neglecting these steps increases the risk of equipment failure and potential falls.

Use of Fall Protection and Safety Harnesses

Fall protection and safety harnesses are essential for minimizing risks when working at height. Harnesses must be correctly fitted and attached to secure anchor points. They should meet industry standards and be regularly inspected for damage or wear. Proper training is crucial to ensure employees understand how to use and maintain fall protection systems. Hard hats and other personal protective equipment should complement harnesses for comprehensive safety. Employers must ensure that fall protection systems are tailored to the specific task and environment, providing adequate protection against falls and potential impact forces. Regular checks and maintenance of harnesses and anchor points are vital to prevent equipment failure.

Safe Work Practices at Height

Safe work practices ensure control measures are implemented, including proper equipment, regular inspections, and adherence to safety protocols to minimize risks during height-related tasks.

Proper Use of Ladders and Scaffolding

Using ladders and scaffolding safely is crucial for minimizing risks. Always visually inspect equipment before use and ensure it is in good condition. Ladders should be placed on firm, level ground and secured if necessary. Scaffolding must be erected by trained personnel and regularly inspected. Three-point contact should be maintained when climbing ladders. Load limits should never be exceeded, and appropriate safety harnesses should be worn when working at heights. Proper use of these tools helps prevent accidents and ensures compliance with safety regulations. Regular training and adherence to manufacturer guidelines further enhance safety practices.

Safe Practices for Mobile Elevating Work Platforms (MEWPs)

Operating Mobile Elevating Work Platforms (MEWPs) safely requires strict adherence to guidelines. Pre-operational checks ensure all functions are working correctly. Operators must be trained and certified to use MEWPs effectively. Always follow the manufacturer’s instructions and load limits. Ensure the work area is clear of obstacles and stable ground conditions. Use fall protection equipment when required. Maintain three points of contact when entering or exiting the platform. Regular maintenance and inspections are essential to prevent mechanical failures. Proper planning and risk assessments before each task help minimize hazards associated with MEWPs, ensuring a safer working environment for all personnel involved.

Training and Competence

Proper training ensures workers understand height-related risks and safety protocols, reducing incidents through competence and adherence to best practices, with regular updates to maintain proficiency and safety standards.

Training Requirements for Workers at Height

Comprehensive training is essential for workers at height, encompassing hazard identification, equipment usage, and rescue procedures. Employers must ensure all staff undergo regular, accredited programs tailored to their roles, covering ladder safety, scaffolding, and MEWPs. Training should emphasize the proper use of fall protection gear, such as harnesses, and the importance of following safety protocols. Refresher courses are necessary to maintain competence, while site-specific training addresses unique risks. Competency certification must be renewed periodically, ensuring workers stay updated on the latest techniques and regulatory changes. This structured approach minimizes risks and fosters a culture of safety in height-related tasks.

Ensuring Competency in Height-Related Tasks

Competency in height-related tasks is achieved through rigorous training and continuous assessment. Employers must verify that workers demonstrate proficiency in using equipment, understanding safety protocols, and applying risk assessment findings. Supervisors should observe tasks to ensure adherence to safe practices and provide feedback. Regular performance reviews and practical evaluations help maintain high standards. Additionally, fostering a culture of continuous learning encourages workers to stay informed about new techniques and equipment. This proactive approach ensures that all personnel are capable of performing their duties safely and effectively, reducing the likelihood of incidents while working at height.

Emergency Preparedness and Response

Emergency preparedness is critical for working at height, requiring a well-defined response plan, regular drills, and clear communication systems to ensure prompt and effective action during incidents.

Rescue Planning for Falls from Height

Rescue planning for falls from height is essential to minimize harm and ensure prompt assistance. A well-prepared rescue plan involves trained personnel, appropriate equipment, and clear communication. Rescue teams should be equipped with harnesses, ropes, and lifting devices to safely retrieve individuals. Regular drills and simulations ensure readiness. Effective coordination between emergency services and workplace teams is critical. Rescue plans must be tailored to specific work environments and heights. Documentation of rescue procedures ensures accountability and compliance with safety regulations. Regular reviews and updates of rescue plans are necessary to adapt to changing work conditions and equipment advancements. Preparedness saves lives in height-related emergencies.

First Aid and Medical Response for Height-Related Injuries

First aid and medical response are critical for managing injuries from falls or accidents at height. Immediate actions, such as stabilizing the injured individual and preventing further harm, are essential. Trained first responders should assess the situation, provide basic life support, and administer care for injuries like fractures, head trauma, or spinal injuries. Proper immobilization techniques, such as using neck collars or backboards, are vital to prevent further damage. Prompt evacuation to medical facilities is often necessary, and communication with emergency services is key. Employers must ensure that first aid kits are accessible and that staff are trained in responding to height-related incidents effectively.

Case Studies and Real-World Examples

Real-world examples highlight the importance of effective risk assessments, showcasing successful implementations and lessons learned from incidents involving working at height.

Examples of Successful Risk Assessment Implementation

Several organizations have successfully implemented risk assessments for working at height, reducing incidents significantly. For instance, a manufacturing company conducted a thorough risk assessment, identifying hazards such as unstable scaffolding and inadequate fall protection. They implemented measures like regular equipment inspections and employee training, leading to a 40% reduction in height-related incidents. Another example is a construction firm that used a risk assessment matrix to evaluate tasks involving ladders and mobile elevating work platforms (MEWPs), ensuring compliance with safety standards and preventing accidents. These examples demonstrate how systematic risk assessments can enhance safety and operational efficiency in various industries.

Lessons Learned from Incidents Involving Working at Height

Incidents involving working at height often highlight the importance of proper risk assessments and safety measures; Many cases reveal that falls occur due to inadequate equipment, poor maintenance, or insufficient training. For example, a lack of proper harnesses or unstable scaffolding has led to fatal accidents. Additionally, failure to conduct thorough risk assessments before tasks has resulted in preventable injuries. These incidents emphasize the need for regular equipment inspections, proper training, and adherence to safety protocols. They also underscore the importance of rescue planning and first aid preparedness to mitigate the consequences of falls. Learning from these incidents is crucial for improving height safety practices.

Continuous Improvement and Monitoring

Continuous improvement ensures ongoing safety by regularly reviewing and updating risk assessments, monitoring compliance with safety protocols, and implementing feedback to enhance height-related work practices.

Regular Review and Update of Risk Assessments

Regular review and update of risk assessments ensure that safety measures remain effective and relevant. This process involves reassessing hazards, considering changes in work environments, and incorporating new equipment or procedures; Factors such as weather conditions, equipment wear, and updated regulations may necessitate revisions. Reviews should occur periodically or whenever significant changes impact the workplace. Collaboration with stakeholders, including workers and safety experts, helps identify overlooked risks and improves the assessment’s accuracy. Documentation of updates ensures transparency and accountability. Failing to review and update risk assessments can lead to outdated controls, increasing the likelihood of incidents. Regular reviews are essential for maintaining a safe working-at-height environment.

Monitoring Compliance with Safety Protocols

Monitoring compliance with safety protocols ensures that risk assessment measures are effectively implemented and followed. This involves regular audits, inspections, and observations to verify adherence to established safety procedures. Supervisors and safety officers play a crucial role in enforcing compliance, identifying deviations, and addressing them promptly. Training and awareness programs help employees understand and follow protocols. Documentation of monitoring activities provides a record of compliance and highlights areas needing improvement; Non-compliance can result in heightened risks, making consistent monitoring essential for safeguarding workers. By maintaining vigilance, organizations can uphold safety standards and reduce incidents associated with working at height.

Effective risk assessment and compliance with safety protocols are paramount for minimizing height-related risks. Continuous improvement ensures safer work environments and protects workers from potential hazards.

Summarizing Key Points for Effective Risk Assessment

Effective risk assessment for working at height requires a systematic approach to identify hazards, evaluate risks, and implement controls. Prioritize tasks to eliminate or reduce risks using hierarchy of controls. Ensure thorough hazard identification, considering both physical and psychological factors. Develop clear safety protocols and communicate them to all workers. Regularly review and update assessments to adapt to changing conditions. Use tools like risk assessment matrices to streamline the process. Always ensure equipment is inspected and maintained, and provide proper training to enhance competency. Document findings and actions to ensure accountability and continuous improvement in height safety practices.

The Future of Height Safety and Risk Management

The future of height safety and risk management lies in advancing technologies, sustainable practices, and enhanced regulatory frameworks. Innovations like wearable safety devices and AI-driven monitoring systems will revolutionize risk detection and prevention. Emphasizing proactive measures, such as predictive maintenance for equipment and real-time hazard monitoring, will reduce incidents. Sustainability will play a key role, with eco-friendly equipment and energy-efficient solutions gaining prominence. Continuous improvement in training programs, incorporating virtual reality for immersive learning, will ensure higher competency levels. Collaboration between industries and regulatory bodies will foster standardized best practices, ensuring safer environments for all workers at height.

Additional Resources

Explore PDF guides, templates, and checklists for conducting thorough risk assessments when working at height, ensuring compliance with safety standards and regulations.

Recommended Reading and Guidelines for Working at Height

Access comprehensive guides like “Work at Height Safety: Hazards and Control Measures” for detailed insights into mitigating risks. Utilize the HSE’s “Falls from Height” guidance and templates for structured assessments. Explore the Risk Assessment Matrix to evaluate tasks involving ladders, scaffolds, and MEWPs. Refer to “The Management of Health and Safety at Work Regulations 1999” for legal compliance. Download the Working at Height Risk Assessment Template to systematically identify hazards and implement controls. These resources provide practical tools and best practices to enhance safety and ensure adherence to regulatory standards, helping organizations create safer environments for employees working at height.

Templates and Tools for Conducting Risk Assessments

Utilize the Risk Assessment Matrix to evaluate tasks involving ladders, scaffolds, and MEWPs. The Working at Height Risk Assessment Template aids in systematic hazard identification and control implementation. Tools like the Hazard Identification Checklist and Safety Inspection Forms ensure thorough preparation. Refer to the Falls from Height Risk Assessment Guide by the HSE for detailed strategies. These resources help organizations organize and prioritize risks, ensuring compliance with regulations like The Management of Health and Safety at Work Regulations 1999. They also provide practical frameworks for documenting and reviewing assessments, making them essential for enhancing workplace safety and reducing height-related risks effectively.